By using the strain effect of metal conductors, the strain gage attached to PCBA can be quantified by the change of its own resistance value when PCBA deforms and becomes mechanically deformed. The quantified strain can be compared with the ultimate strain to determine the risk of PCBA deformation to components or tin point rupture of components. Provide direction for PCBA process improvement measures.

The strain test system detects the voltage change caused by the change of strain gauge resistance through Wheatstone bridge, and then converts the voltage change into strain through the program in the strain test software.

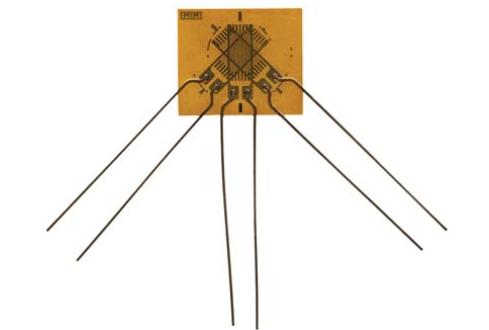

The strain flower is a strain gauge containing three independent sensitive grids, which are stacked on each other at a common point to measure the strain along their respective axes at a common point.

Strain is defined as (length change)/(original length), is a dimensionless physical quantity, in the PCBA strain test, because the strain value is very small, usually described by microstrain (με), according to 106* (length change)/(original length) to define microstrain.

In the PCBA strain test, the strain state of PCBA is the plane strain state. The strain test analysis system can calculate the main strain and strain rate in the PCBA process by measuring the real-time strain value in the three directions of the strain flower, so as to judge whether the product strain of the process exceeds the standard.

Steps beyond the strain limit are considered excessive and are identified for corrective action. Strain limits can be derived from customer, component supplier, or well-known practices within the enterprise/industry (derived from IPC_JEDEC-9704A).

Where the principal strain is the largest and smallest orthogonal strain in a plane, perpendicular to each other and the tangent strain in the direction is zero. In PCBA strain test, the principal strain is usually calculated by measuring as the critical metric criterion. The strain rate indicates the rate of strain change per unit time, which is used to measure the damage risk of components.

Strain gage

IPC_JEDEC-9704A

Strain test analysis system

Post time: Apr-22-2024