Destructive Physical Analysis

Service Introduction

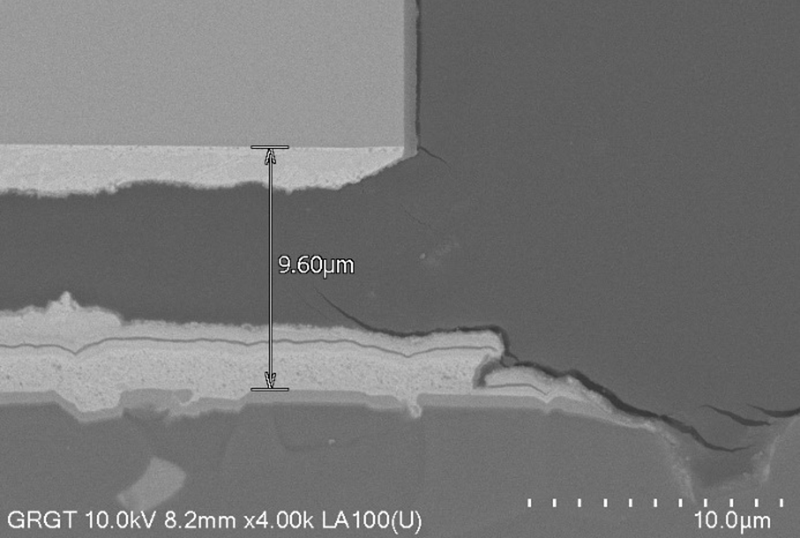

GRGT provides destructive physical analysis (DPA) of components covering passive components, discrete devices and integrated circuits.

For advanced semiconductor processes, the DPA capabilities covers chips below 7nm, the problems could be locked in the specific chip layer or um range; for aerospace-level air-sealing components with water vapor control requirements, the PPM-level internal water vapor composition analysis could be performed to ensure the special use requirements of air-sealing components.

Service Scope

Integrated circuit chips, electronic components, discrete devices, electromechanical devices, cables and connectors, microprocessors, programmable logic devices, memory, AD/DA, bus interfaces, general digital circuits, analog switches, analog devices, microwave Devices, power supplies, etc.

Test standards

● GJB128A-97 Semiconductor discrete device test method

● GJB360A-96 electronic and electrical components test method

● GJB548B-2005 Microelectronic device test methods and procedures

● GJB7243-2011 Screening Technical Requirements for Military Electronic Components

● GJB40247A-2006 Destructive Physical Analysis Method for Military Electronic Components

● QJ10003—2008 Screening Guide for Imported Components

● MIL-STD-750D semiconductor discrete device test method

● MIL-STD-883G microelectronic device test methods and procedures

Test items

|

Test type |

Test items |

|

Non-destructive items |

External visual inspection, X-ray inspection, PIND, sealing, terminal strength, acoustic microscope inspection |

|

Destructive item |

Laser de-capsulation, chemical e-capsulation, internal gas composition analysis, internal visual inspection, SEM inspection, bonding strength, shear strength, adhesive strength, chip delamination, substrate inspection, PN junction dyeing, DB FIB, hot spots detection, leakage position detection, crater detection, ESD test |

Related PRODUCTS

-

Phone

-

E-mail

-

Top