Corrosion mechanism and fatigue test

Service Introduction

Corrosion is an ever-present, continuous cumulative process, and often an irreversible process. Economically, corrosion will affect the service life of equipment, cause equipment damage, and also bring other indirect losses; In terms of safety, serious corrosion may lead to casualties. GRGTEST provide Corrosion mechanism and fatigue test services to avoid losses.

Service scope

rail transit, power plant, steel equipment manufacturers, dealers or agents

Service standard

● GB/T 10125 Artificial atmosphere corrosion test salt spray test

● ISO 9227 Corrosion tests in artificial atmospheres- Salt spray tests

● GB/T1771 Paints and varnishes -- Determination of resistance to neutral salt spray

● GB/T 2423.17 Electrical and electronic products - Environmental testing - Part 2: Test methods - Test Ka: salt spray

● GB/T3075 Metal materials fatigue test axial force control method

● GB/T 13682 fatigue test method for axial load on threaded fasteners

● GB/T 35465.1 Polymer matrix composites - Test methods for fatigue properties - Part 1: General rules

● GB/T 35465.2 Test methods for fatigue properties of polymer matrix composites - Part 2: Statistical analysis of linear or linearized stress life (S-N) and strain life (E-N) fatigue data

● GB/T 35465.3 - Part 3: Pull-pull fatigue

Service program

Through the corrosion test, it can not only test and evaluate the corrosion performance of the materials and components of the product, but also analyze and study the corrosion phenomenon and corrosion mechanism, so as to provide material selection and improvement and optimization suggestions for the corrosion protection design of the product during use.

● Comprehensive corrosion test: chemical reagent immersion test, composite salt spray test, simulated seawater immersion test, etc.

● Local corrosion test: galvanic corrosion, selective corrosion, stress corrosion, intergranular corrosion.

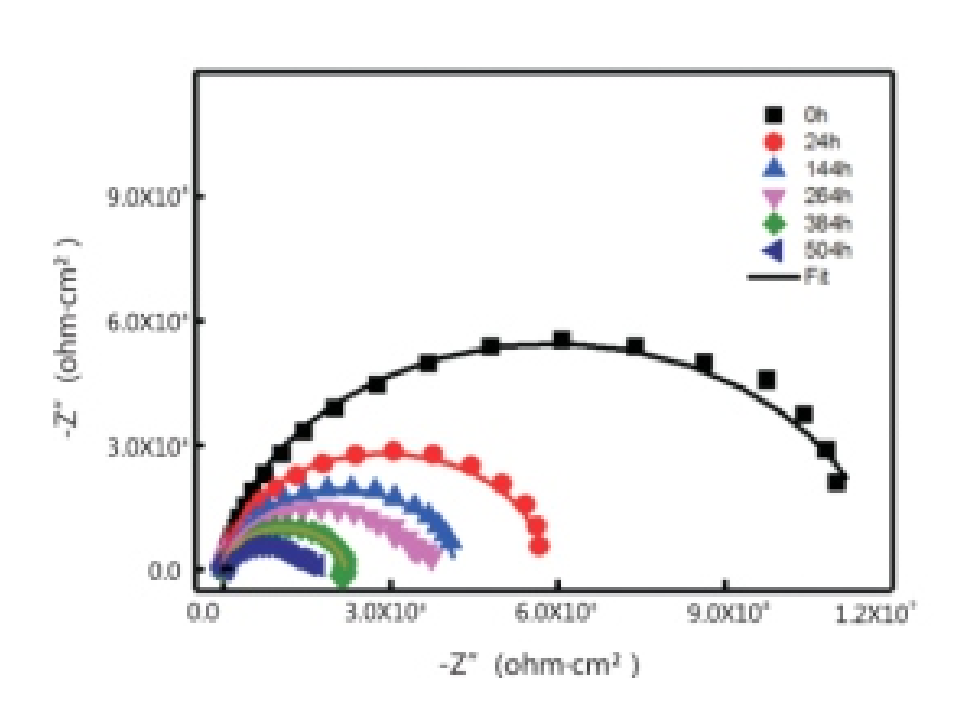

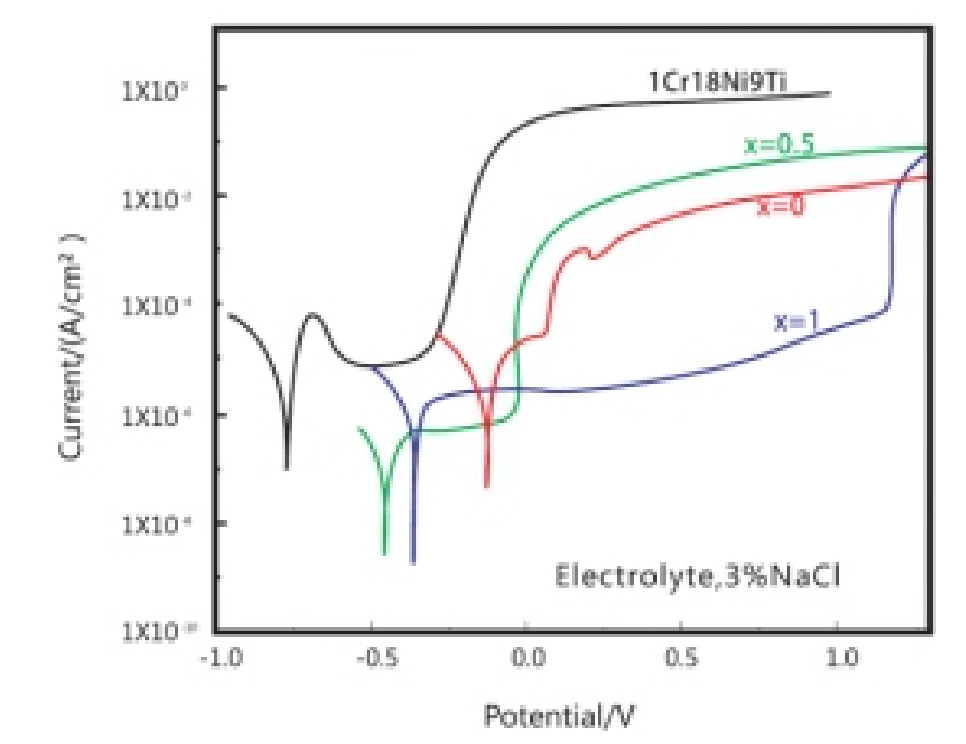

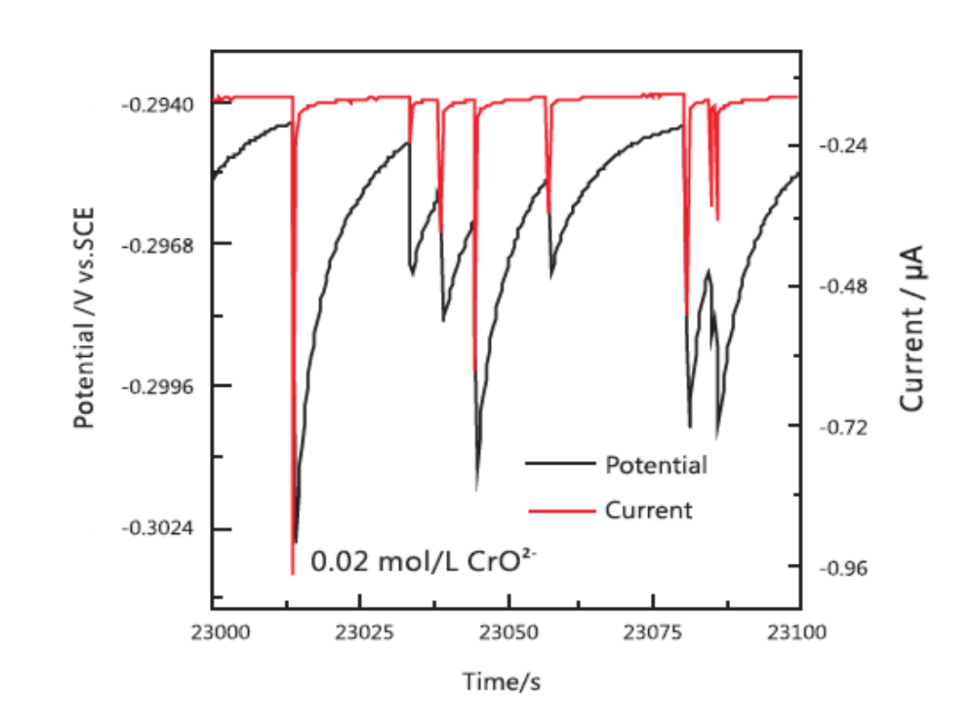

● coating Study of kinetics and corrosion mechanism of coatings or metal materials.

● electrochemical noise, electrochemical impedance, etc.

Related PRODUCTS

-

Phone

-

E-mail

-

Top